Product optimisation by use of 3D-print

Holder for robot grappling claw got a ‘pusher’ created in 3D-print

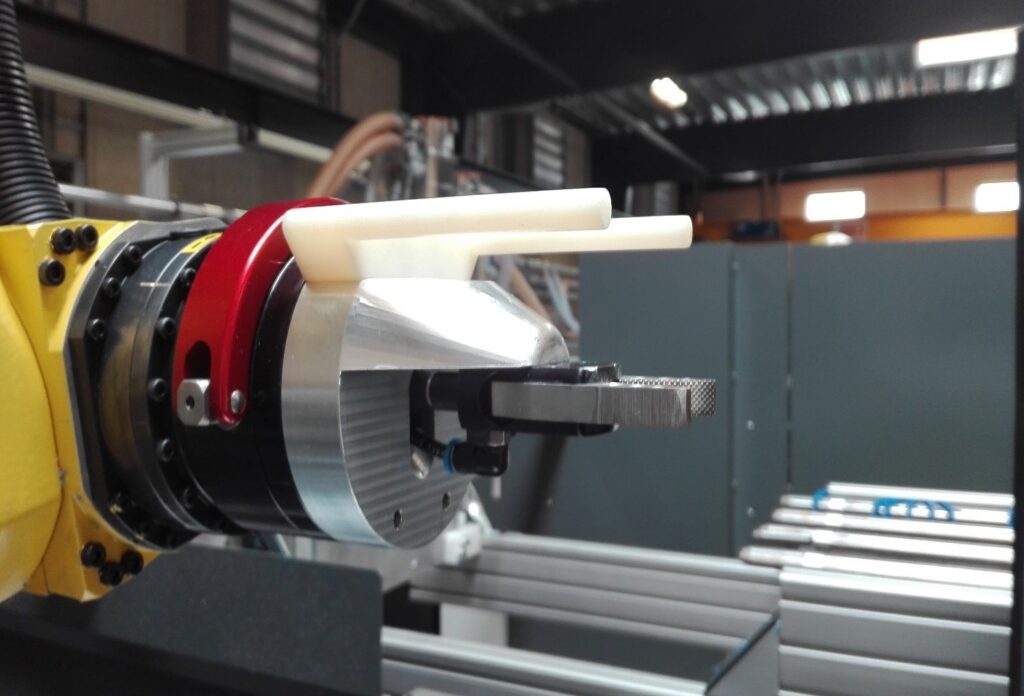

Uni-Technology had been commissioned to make a holder for a grappling claw to be mounted on a robot.

There ware several requirements for the workpiece. Among other things the holder should fit a locking mechanism on the robot, that the claw should be mounted on the workpiece. Finally, it should be posible to lead an air hose through the workpiece to the claw.

The workpiece was designed in Mastercam and then produced in a CNC milling machine.

When the parts were assembled and mounted on the robot, it did not work optimally. The things the robot had to take and put in place could move.

Therefore, a “pusher” was developed to push things into place. However, there was still a problem. The pusher was not allowed to weigh much, as the weight limit for the robot’s tools had almost been reached.

To solve this problem, Jacob from the production team had the idea to 3D-print the pusher, as the weight would be very low.

It also gave the advantage in case a mistake occurred. Then it would be the plastic-printed pusher that broke instead of an expensive item or claw.

The pusher was also designed in Mastercam and then produced as a 3D-print in one of our 3D printers.

Task and problem solved.

Contact us and let us set your idea into production

Sales, development and production

- Thomas Nørmølle

- tn@unitechnology.dk

- +45 53 85 07 27

- Kim Meyer

- km@unitechnology.dk

- +45 28 96 18 33

Climate-ready Production Company

Latest cases og news

Uni-Technology A/S acquires the activities of Stensved Formværktøj ApS

Press release The Vejle based tool manufacturer Uni-Technology A/S has through the newly established subsidiary

2023 will be another good year for Uni-Technology

2022 was a great and busy year, where we despite various crises at home and

Green is the new black

Case story from DI Business 10 November 2022 In early summer 2022, Uni-Technology A/S in